Plastic CNC machining has emerged as a pivotal technology in modern manufacturing, enabling the production of a diverse range of components with precision and efficiency. At the forefront of this transformative field is 3ERP, a leading service provider offering an extensive array of plastic CNC machining types and processes. With a commitment to innovation and quality, 3ERP has become a reliable partner for industries seeking tailored solutions.

From CNC milling to injection molding, this comprehensive overview aims to shed light on the versatility and capabilities that make 3ERP a go-to resource in the realm of plastics machining. In this exploration, we delve into the world of 3ERP Plastic CNC Machining, uncovering many supported types and processes that cater to a myriad of manufacturing needs.

Exploring 3ERP Plastic CNC Machining

3ERP, a leading manufacturing service provider, has established itself as a key player in the realm of plastic CNC machining. Leveraging cutting-edge technology and a commitment to precision, 3ERP offers a diverse range of services that cater to various industries. In this article, we will delve into the extensive array of plastic CNC machining types and processes supported by 3ERP, providing a comprehensive understanding of their capabilities.

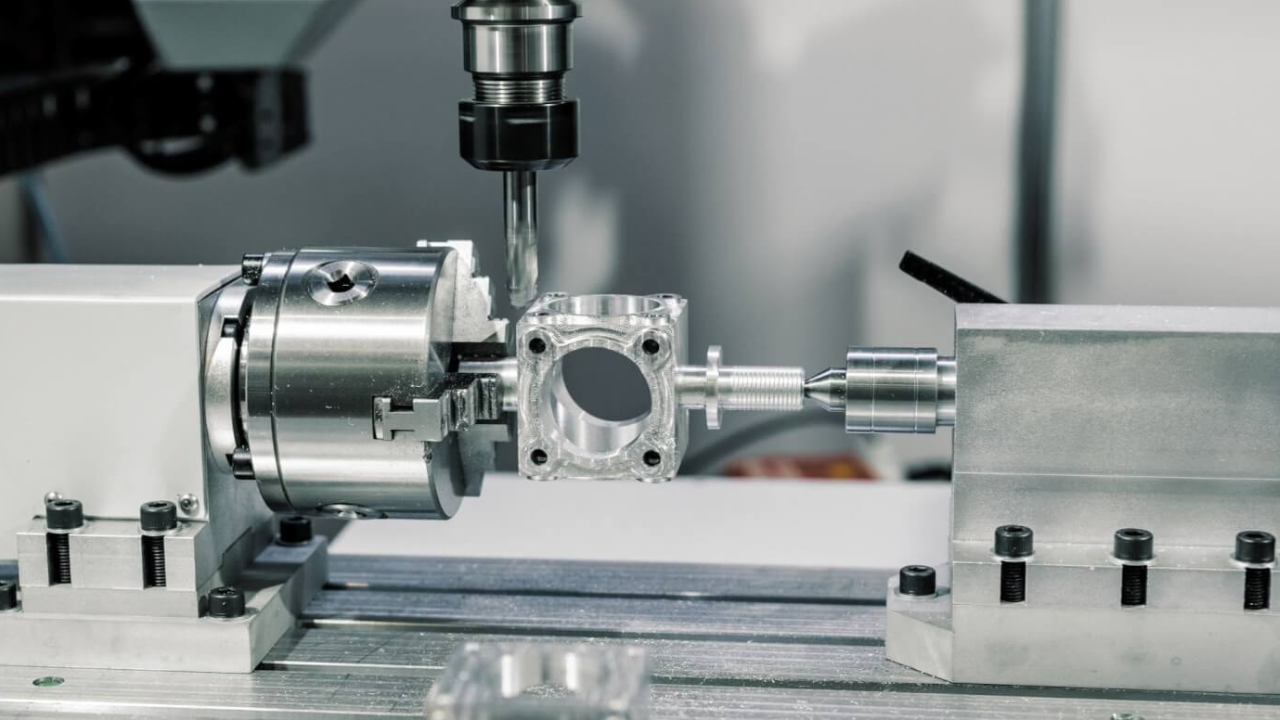

CNC Milling

One of the primary plastic CNC machining processes offered by 3ERP is CNC milling. This technique involves the removal of material from a plastic workpiece using rotary cutters. 3ERP's state-of-the-art milling machines ensure accuracy and efficiency in producing intricate plastic components.

CNC Turning

3ERP offers CNC turning as a fundamental service, specializing in the creation of cylindrical parts by rotating a plastic workpiece against cutting tools. Demonstrating precise control throughout the turning process, 3ERP ensures the production of high-quality plastic components with meticulous attention to tight tolerances.

CNC Routing

Catering to projects with intricate designs and shapes, 3ERP provides CNC routing services. This process utilizes a computer-controlled router to meticulously carve precise patterns from plastic sheets. Renowned for its versatility, CNC routing is an ideal solution for creating prototypes, signage, and custom plastic components.

Injection Molding

3ERP's injection molding capabilities are crucial for the mass production of plastic parts. This process involves injecting molten plastic into a mold, creating detailed and consistent components. 3ERP's expertise ensures efficient production with minimal waste.

Vacuum Casting

Tailored for low-volume production needs, 3ERP offers a cost-effective solution through vacuum casting. This technique employs silicone molds to replicate detailed plastic prototypes, ensuring the preservation of high-quality finishes and intricate features. Also, it is one of the famous methods for casting.

Thermoforming

Utilizing thermoforming techniques, 3ERP specializes in crafting plastic components through the heating and molding of plastic sheets. This method is well-suited for the production of large, lightweight parts, providing a rapid and cost-effective solution for a diverse range of applications.

3D Printing

Incorporating advanced 3D printing technologies, 3ERP offers rapid prototyping services. Moreover, this allows clients to validate their designs before moving into mass production. Also, it ensures a streamlined and cost-effective development process. Mainly it is famous due to its printing quality.

Polyurethane Casting

3ERP leverages polyurethane casting to manufacture premium prototypes and low-volume plastic parts. This method encompasses pouring liquid polyurethane into molds, resulting in the production of robust and intricately detailed components available in a variety of surface finishes.

Compression Molding

Specializing in the creation of large and intricate plastic components, 3ERP's compression molding services are designed to meet the demands of complex projects. This method entails placing plastic material into a heated mold and applying compression to attain the desired shape, ensuring both consistency and efficiency in the manufacturing process.

CNC Engraving

When intricate designs or detailed markings are essential for projects involving plastic surfaces, 3ERP offers specialized CNC engraving services. This precise technique not only enhances customization but also facilitates branding on plastic components, ensuring the incorporation of intricate and finely detailed designs.

Conclusion

3ERP's plastic CNC machining services encompass a wide range of cutting-edge processes, allowing clients to meet their diverse manufacturing needs. Whether it's CNC milling, injection molding, 3D printing, or any of the other supported techniques, 3ERP's commitment to quality and precision makes it a reliable partner for industries seeking top-notch plastic components.