Stamps are not only used in mailing services they are used in business, law, and art among other fields electronic engraving machines have made the creation of stamps to be more precise and flexible as compared to the past. In this article, read more about how these advanced machines enhance stamp production.

History of Stamp-Making Technology

The traditional methods of making stamps required a lot of handwork and this was very time-consuming and could result in many variations. Electronic engraving machines have been of great importance in the industry as a major revolution. These machines are more accurate and faster than any manual method that may be used in the process.

Electronic Engraving Machines Work

Electronic engraving machines use a process that is partly mechanical and partly computerized. Here's a simplified overview of the process.

Design Input

The process begins with a digital design. This design is normally created in graphic design software and then saved and exported to the computer of the engraving machine. The digital format allows the designer to have better control over the design aspects.

Material Preparation

The inked material may be rubber or polymer which is then fed into the stamping machine. Electronic engraving machines can be used with various materials like rubber and polymer.

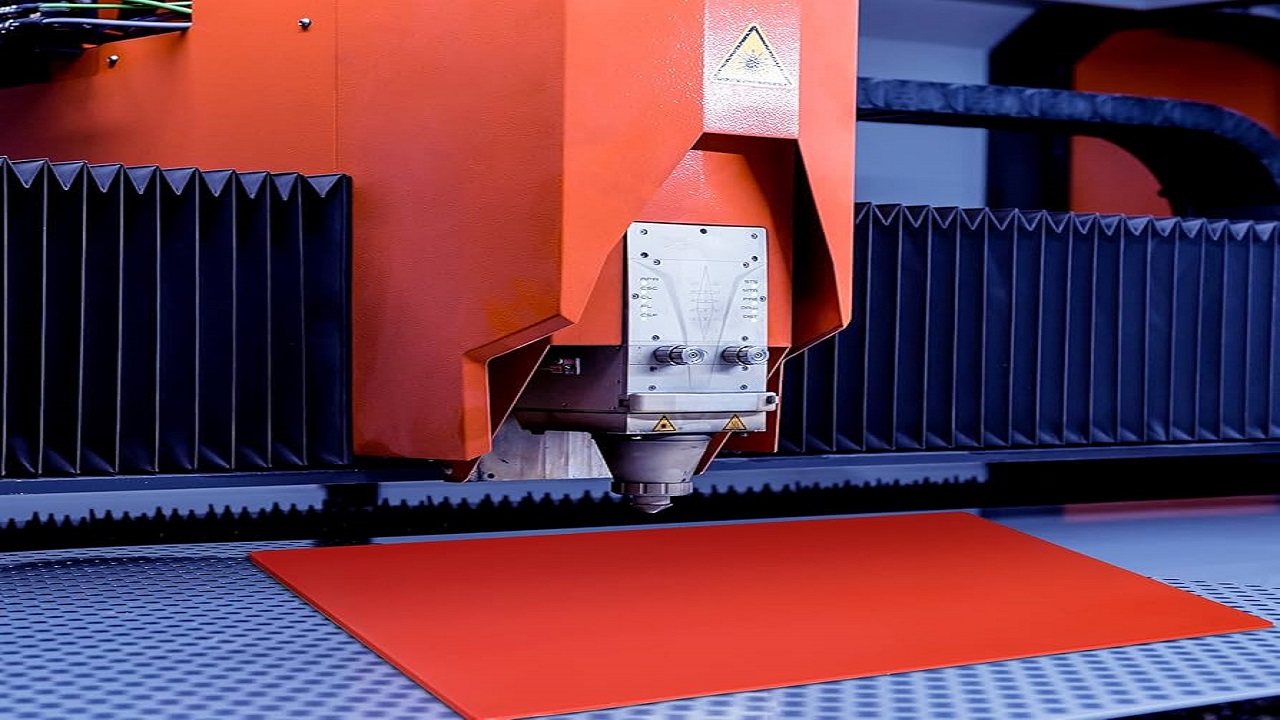

Engraving Process

People know that software in the computer is integrated with the engraving machine that engraves the design on the stamp material. The benefit of using electronic engraving machines is that they can engrave at high resolution and therefore fine details can be engraved.

Benefits of Using Electronic Engraving Machines for Stamps

Precision and Accuracy

Electronic engraving machines are very accurate as compared to other engraving machines. The digital design is then placed on the material with accuracy to ensure that all the details of the stamp are imprinted to the detail.

Efficiency and Speed

Stamp-making uses electronic engraving machines, and they assist in reducing the time taken in the process. However, it may take hours or even days to achieve the same goal through manual means, but it can be done in a shorter time.

Consistency

Electronic engraving machines enable the manufacturing of stamps to be uniform. This consistency is very useful for companies and institutions that require their logos and official papers to have a certain look.

Flexibility

These machines are very versatile and can operate on various types of materials and styles of the products to be manufactured. Electronic engraving machines can be used for any kind of stamping, starting from the simple text stamp and ending with the logo.

Applications of Engraved Stamps

Engraved stamps are used in various fields and for various purposes. In business, they are used in branding, labeling, and official documentation. People use them for certificates and awards in organizations and schools. In personal crafting, engraved stamps are used in arts and crafts and scrapbooking.

Conclusion

Electronic engraving machines have taken over the traditional methods of stamp making because of the precision, efficiency, and versatility that come with the use of the machines. These machines employ advanced technology to ensure that each stamp is an original of the digital design and therefore offer the best quality stamps. In the future, with the development of technology, the applications of electronic engraving machines will be more, so the application of stamp making, and other fields will increase.