Fire safety is a paramount concern in any built environment, whether it's a residential, commercial, or industrial setting. One crucial aspect of ensuring fire safety is the use of appropriate materials and standards in constructing fire protection systems. ASTM A795 is a key standard in this regard, providing specifications for seamless and welded steel pipe used for fire protection systems. Understanding ASTM A795 standards is essential for architects, engineers, builders, and anyone involved in the design and construction of fire protection systems. For more detailed information on ASTM A795 standards, visit page or consult with industry experts in fire protection engineering and construction.

What is ASTM A795?

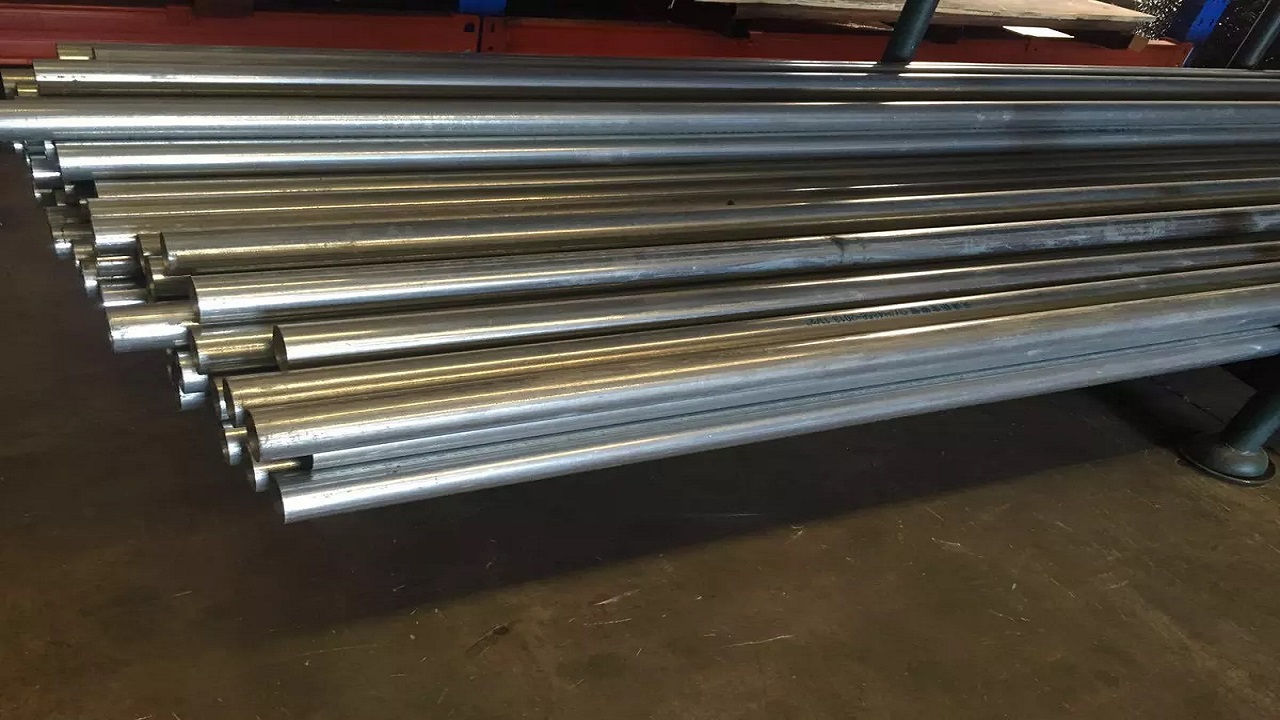

The American Society for Testing and Materials (ASTM) published standard ASTM A795, which details the specifications for seamless, black, and hot-dipped zinc-coated (galvanized) steel pipes intended for use in firefighting. This standard applies to pipes with nominal sizes between 1/2 and 10 inches. It can be used in steam, water, gas, and aviation as well as mechanical and pressure applications.

Key Requirements of ASTM A795

Material Composition

ASTM A795 mandates specific requirements for the chemical composition of the steel used in the manufacturing of pipes. This ensures that the material possesses the necessary properties to withstand high temperatures and pressures during fire incidents.

Manufacturing Process

The standard outlines the manufacturing processes for both welded and seamless pipes. These processes include forming, welding, and heat treatment, among others, to ensure the integrity and strength of the pipes.

Coating

One crucial aspect of fire protection pipes is their resistance to corrosion. ASTM A795 requires pipes to be either black or hot-dipped galvanized to provide corrosion protection, particularly in humid or corrosive environments.

Dimensional Tolerances

The standard specifies dimensional tolerances for wall thickness, outside diameter, and length to ensure uniformity and compatibility with fittings and couplings used in fire protection systems.

Importance of Compliance

Compliance with ASTM A795 standards is vital for several reasons:

Fire Safety

Pipes that meet ASTM A795 standards are designed to withstand the rigors of fire incidents, ensuring the integrity of fire protection systems when they are needed most.

Reliability

By adhering to established standards, builders and contractors can ensure the reliability and performance of fire protection systems over the long term.

Legal and Regulatory Requirements

Many jurisdictions require compliance with recognized standards such as ASTM A795 for fire protection systems. Non-compliance can lead to legal liabilities and may result in rejection during inspections.

Future Developments

As technology and industry practices evolve, so do standards like ASTM A795. It's essential for stakeholders in the construction and fire protection sectors to stay updated on any revisions or additions to these standards. Additionally, advancements in materials science and engineering may lead to the development of new materials or techniques for enhancing fire safety in buildings.

Conclusion

Understanding ASTM A795 standards is essential for ensuring the effectiveness and reliability of fire protection systems. By adhering to these standards, architects, engineers, builders, and other stakeholders can contribute to creating safer built environments. Compliance with ASTM A795 not only enhances fire safety but also ensures the longevity and performance of fire protection systems.